X-RAY REFLECTOMETER

General Description

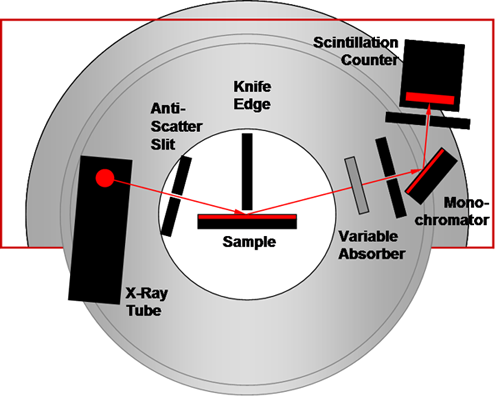

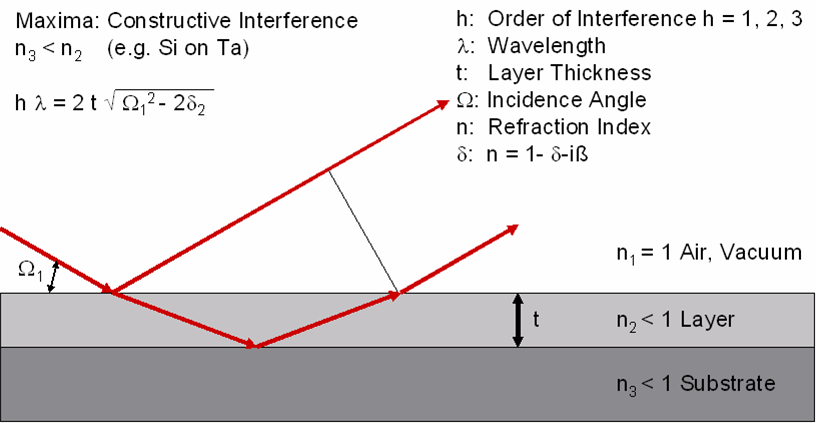

The refractive index for x-rays is sligtly smaller than 1, mainly determined by the material density. Therefore an incident x-ray beam is split into a reflected and refracted beam at the interface between two material or the surface. With respect to the coherence length of these beams, interferences can be observed above the critical angle of total reflection. The effect, discovered in the 1930’s by Kiessig, was cultivated by computer simulations to a very efficient metrology method for thin films in the thickness range between a few nanometers up to a few hundred nanometers. From the interference pattern the layer thickness, -density and interface roughness can be determined using computer simulations and refinement, even for multiple layer structures. Especially for the thickness measurement XRR is the method with the highest precision at an absolute scale. Often the method is therefore used for the calibration of other techniques like ellipsometry. The XRR system of LabXA uses a parallel Cu-Kα beam and a knife-edge diaphragm to define the beam collimation the resolution is about 0.01°.

X-Ray Reflektometry - reflexion on a single layer.

Analytical parameters in X-Ray Reflectometry [Bruker AXS].

Characteristics

| • | Diffractometer with automated theta /2theta tuning; Multirange operation |

| • | Radiation: Cu-Kα. |

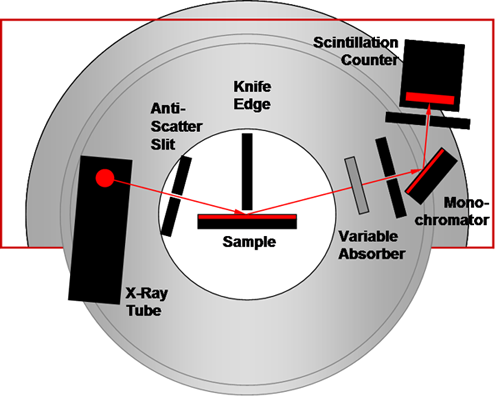

| • | Beam path: Parallel-beam, knife edge diaphragm; sec. graphite monochr. |

| • | Intensity: High dynamical range up to 108 using beam absorbers |

| • | Samples: - Substrates: Flat and smooth glass, Si-wafers or highly polished metal surfaces (Roughness: ‹ 3 nm) - Thin films: crystalline, amorphous, heterogenious layer sequences (including periodic multilayers), graded layers |

| • | Layer thickness: 1 - 300 nm. |

| • | Irradiated area: 10 mm x 10 mm. |

| • | Thickness error: ‹ 0.5 %. |

| • | Density error: 2 % |

| • | RMS roughness: 0.1 - 3 nm. |

Applications

Thin films and film systems on smooth surfaces like Si wafers (metallization films, dielectric films, diffusion barriers, photoresists, wafer roughness) and float glass for architectural and automotive industry (thermo-reflecting, anti-reflecting, electro-chromic coatings).

| Example 1: | (In,Sn)O2 on glass - influence on layer thickness. |

| Example 2: | TaO / Ta / SiO2-layer system on a Si-substrate. |

| Example 3: | Roughness of Ti-layers on Si - variation of Sputter-parameters. |

Example 1: (In,Sn)O2 on glass - influence on layer thickness.

Example 2: TaO / Ta / SiO2-layer system on a Si-substrate.

Example 3: Roughness of Ti-layers on Si - variation of Sputter-parameters.