PARALLEL-BEAM DIFFRACTOMETER

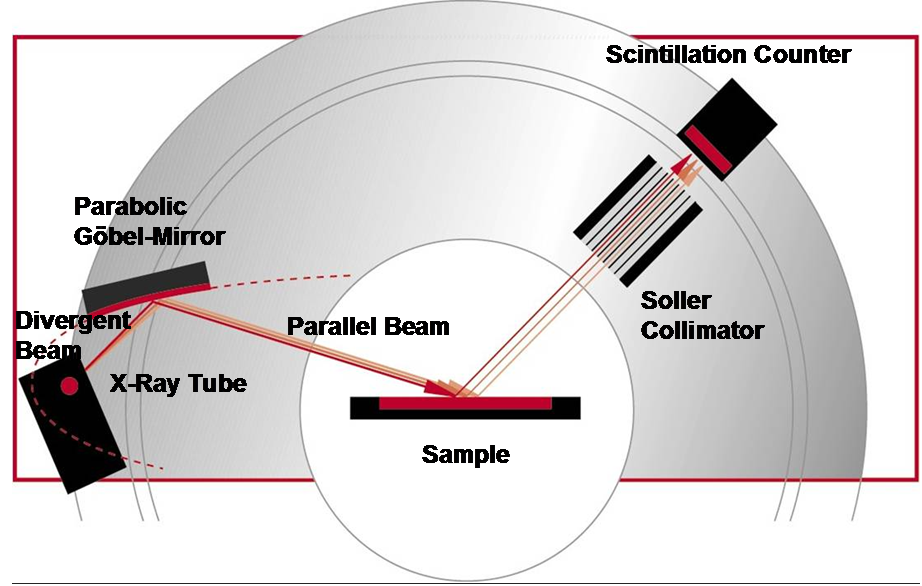

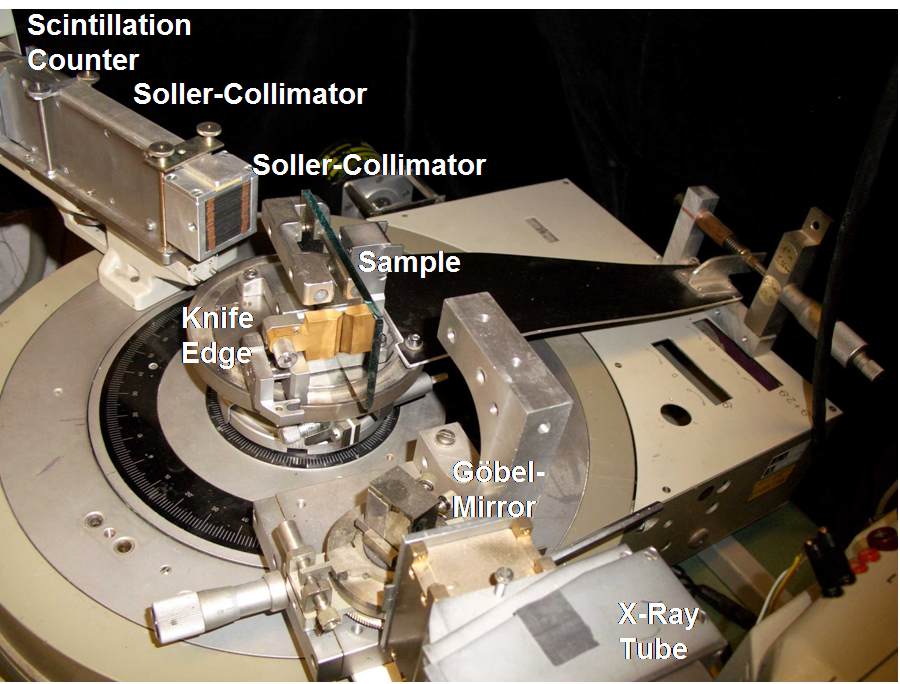

Parallel-Beam diffractometer with parabolic Göbel-Mirror for powder diffraction [Bruker AXS].

General Description

In focussing powder diffraction techniques like the

Bragg-Brentano method, the sample surface geometry is an optical imaging element contributing

to the peak shape and position of the diffracted beams. The sample artefacts are described as

"sample displacement" errors. Instead of collecting the diffracted beams along the focussing

geometrical figure (cylinder) the "Parallel-Beam" techniques avoid these influences by measuring

the direction of the diffracted beam directly. To make this in an efficient way the divergent

primary beam has to be converted into an intense parallel and monochromatric beam using a parabolic

Göbel-Mirror. On the receiving side a long parallel collimator in front of a scintillation counter

defines angular resolution.

The parallel-beam system at LabXA has its main

application for grazing-incidence diffraction

of thin ploycrystalline films. The low angles of incidence in the vicinity of total reflection

allow to control the penetration depth and provide a high signal from the surface at low background

from the bulk. By varying the incidence angle, also a certain depth senitivity can be achieved.

The other main application are the measurements of materials with low absorption (Organics,

Pharma-Products) or bulky parts with odd shaped surfaces (example: tooth wheels).

The parallel beam is also the key for the combination with further crystal optical elements

that are required for high-resolution diffraction (HRXRD) and reflectometry (XRR).

Grazing Incidence X-Ray Diffractometer.

Characteristics

| • | Parabolic Göbel-Mirror |

| • | Monochromatic (Kβ suppression) |

| • | Scintillation counter |

| • | High intensities |

| • | Scanning PSPC |

| • | Low divergence |

| • | No influence of sample displacement |

| • | Samples: powders, massive tablets, parts, layered structures, thin films |

Examples

| Example 1: | Measurement of antique bronze camel (Yemen, 2nd century A.D., courtesy of Museum of Völkerkunde Munich, Germany) by parallel-beam diffraction. |

| Example 2: | Direct measurements through pharmaceutical tablets (identification of active agents in different analysic products). |

| Example 3: | Depth sensitive phase identification of a metallization layer system. The variation of the incidence angle Ω from 0.1° to 2° corresponds with an information depth from about 3 nm to 500 nm. |

| Example 4: | Identification of extremely thin layers for microelectronic applications (high-ε dielectric oxides for memory devices) |

Example 1: Non-destructive measurement of antique bronze camel (Yemen, 2nd century A.D., courtesy of Völkerkunde Museum Munich, Germany) by parallel-beam diffraction.

Example 2: Direct measurements through pharmaceutical tablets (identification of active agents in different analysic products).

Example 3: Depth sensitive phase identification of a metallization layer system. The variation of the incidence angle Ω from 0.1° to 2° corresponds with an information depth from about 3 nm to 500 nm.

Example 4: Identification of extremely thin layers for microelectronic applications (high-ε dielectric oxides for memory devices)